-

-

- On this page : Lithium &

Ceramics, by Smart2000 (translated by Edouard

Bastarache)

-

-

|

LITHIUM

& CERAMICS

by

Smart2000

|

-

-

- This alkaline metal

is the lightest of known metals (Li, atomic mass

6.941).

-

-

- In ceramics it is found

in the oxidized state, Li2O (molar mass

29.881

-

-

- Classified as the 33th most

abundant element on the planet, this metal is present

in deposits coming from salt lakes, deposits of

silicates (spodumene, petalite, lepidolite), of

phosphates (amblygonite), of phyllosilicates coming

from the modification of volcanic ash (ex: hectorite

in California) and of borates like jadarite

(Serbia).

-

- Today the demand for this

metal for the production of lithium-ion batteries used

in data processing and telephony is enormous. Even if

it is used rather little outside of ceramics its price

currently beats records.

-

- Lithium oxide, Li2O, is the

most potent flux among alkaline oxides, one can

classify it as follows: Li2O > Na2O > K2O. It is

a very active flux which strongly decreases the

viscosity of glazes. According to the proportions

used, it lowers also the thermal dilatation

coefficient of glazes and of ceramic bodies for high

temperature.

-

-

- In current ceramics

lithium is useful :

-

- - In flameware bodies

intended to produce cooking pieces going directly on

the flame (see also the article " Flameware

" by Ron Probst on Smart.Conseil). Li2O reduces the

thermal expansion and improves the properties of

resistance to thermal shock.

-

- - In glazes. Li2O,

introduced from chemicals (carbonate of lithium,

lithium fluoride) or natural mineral compounds

(spodumene, petalite,…), is a powerful flux in

particular when associated with potassium and sodium

feldspars.

- Its melting action begins at

750-780°C. It allows to strongly lower the

viscosity of molten glazes. Used up to 1 to 2% it can

reduce the maturation temperature of a glaze by 50 to

100°C.

- In important additions (>

3%) it strongly reduces the thermal dilatation

coefficient and can lead to shivering (shivering is

the opposite of crazing). Lithium also improves the

resistance to scratching.

-

-

- As a general rule one uses

lithium carbonate when one wants to introduce lithium

alone into a glaze. The melting point of lithium

carbonate is 723°C (in air).

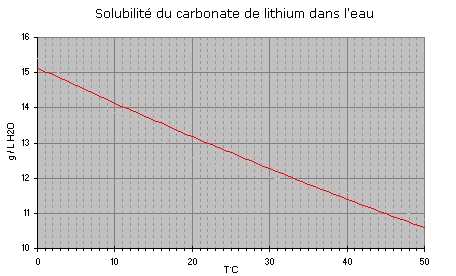

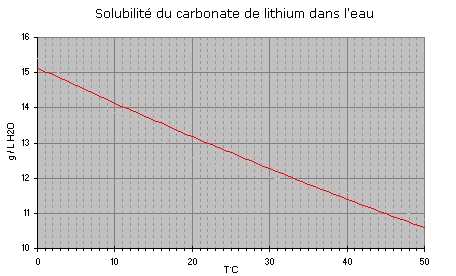

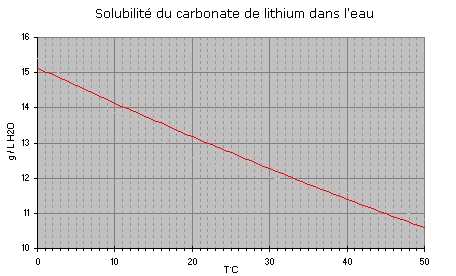

- Lithium carbonate is not

very soluble (13.1 g. per liter of water at 20°C)

contrary to other salts of alkaline elements. This

solubility decreases with the rise in

temperature.

-

-

- Solubility of

lithium carbonate in water

-

- The least soluble raw

materials containing lithium are: lithium carbonate,

lithium frits (rather rare alas…) and minerals

such as spodumene, lithium feldspar, amblygonite and

lepidolite.

-

- In high temperature glazes,

Li2O attacks silica and alumina of the shard, which

allows the formation of an effective transition layer

to lower the tensions of dilatation. That also makes

it possible to make at equal temperature glazes with

more silica and alumina, more stable and more

resistant.

-

-

-

-

- Molar factors of alkaline

oxides for the calculation of the elasticity of

multi-component glasses according to A.A Appen :

-

-

- Li2O : 78.45 Gpa (ou 8 x

10-5 kgf/cm²)

- Na2O : 58.35 GPa (ou 5.95 x

10-5 kgf/cm²)

- K2O : 40.21 GPa (ou 4.1 x

10-5 kgf/cm²)

-

- Li2O increases the

elasticity modules of glazes (approximately twice as

much as K2O).

-

- Chart of natural and

chemical compounds :

-

-

-

|

Mineral Compounds

:

|

Chemical

Formula

|

Li2O%

|

Al2O3%

|

SiO2%

|

Molar

Mass

|

|

Aluminosilicates

:

|

-

|

-

|

-

|

-

|

-

|

|

Eucryptite

(E)*

|

Li2O.Al2O3.2SiO2

|

11.86

|

40.46

|

47.68

|

252

g

|

|

Spodumene

(S)*

|

Li2O.Al2O3.4SiO2

|

8.03

|

27.40

|

64.57

|

372.16

g

|

|

Lithium Feldspar

(R)*

|

Li2O.Al2O3.6SiO2

|

6.07

|

20.71

|

73.22

|

492.32

g

|

|

Petalite

(P)*

|

Li2O.Al2O3.8SiO2

|

4.88

|

16.65

|

78.47

|

612.48

g

|

|

|

|

Other Minerals

:

|

Chemical

Formula

|

Empirical

Formula

|

Li%

|

Molar

Mass

|

|

Amblygonite

|

(Li,Na)Al(PO4)(F,OH)

|

Li0.75

Na0.25 Al(PO4)

F0.75

(OH)0.25

|

3.44

|

147.90

g

|

|

Lepidolite

|

K(Li,Al)3(Si,Al)4

O10

(F,OH)2

|

KLi2AlSi4O10F(OH)

|

3.58

|

388,30

g

|

|

-

|

|

Chemical

Compounds :

|

-Chemical

Formula

|

Li2O%

|

CO2%

|

Li%

|

Molar

Mass

|

|

Lithium

carbonate

|

Li2CO3

|

40.44

|

59.56

|

18.74

|

73.89

g

|

|

Lithium

fluoride

|

LiF**

|

-

|

-

|

26.75

|

25.94

g

|

-

- * : See ternary diagram

hereafter

- ** : 1 mole of LiF (25.94

g) will give 0.5 mole of Li2O in the ceramic product

that is to say 14.94 g

-

-

-

- Ternary diagram

Li2O.Al2O3.SiO2 (L.A.S) :

-

- The ternary diagram

Li2O-Al2O3-SiO2 provides important information

concerning the useful phases for the design of

vitroceramics.

-

- Vitroceramics are ceramic

materials obtained by a controled process of

nucleation-growth applied to an " Ad hoc " vitreous

matrix. These vitroceramic materials are those which

have been most largely used because of their low

dilatation coefficients, null or negative and also for

their thermal and chemical stability.

-

- Examples :

- - Lithium enters culinary

vitroceramics for cooking which go on the flame (ex:

famous pans of amber glass…).

- - Lithium is also used for

the optical vitroceramics intended for telescopes of

utmost precision because they require an extremely low

linear dilatation coefficient.

-

-

- Phase diagrams

Li2O - Al2O3 - SiO2

- with indication

of the vitreous zones in yellow,

- of the lithium

compounds P = Petalite, R = Lithium Feldspar, S =

Spodumene, E = Eucryptite

- and of the zones

with negative thermal dilatations I and II in green

-

-

-

-

- The vitreous zone in this

ternary system is crossed by that of minerals with low

or negative thermal dilatation coefficients (points P,

R, S, E in the zones in green). The vitreous compounds

located along the Li2O-Al2O3-SiO2 line present an

aptitude to produce fast crystallizations in -

eucryptite and in - spodumene.

-

-

-

- Extracts of summaries of

publications by V.G. AVETIKOV in connection with

porcelain bodies containing spodumene

:

-

-

- " The ternary system

Li2O-Al2O3-SiO2 (L.A.S.) contains many compounds like

eucryptite (Li2O-Al2O3-2SiO2), spodumene

(Li2O-Al2O3-4SiO2), lithium feldspar

(Li2O-Al2O3-6SiO2) and petalite (Li2O-Al2O3-8SiO2).

These various mineral compounds of lithium are usable

in ceramic pieces."

-

- " Several of these

compounds, and in particular spodumene, used in the

development of ceramic bodies by addition of

argillaceous and mineral matters give very weak

thermal dilatations, and even negative in the range of

temperature going from 0 to 800°C."

-

- => This is what one seeks

with the special bodies that go on the flame.

-

- " For example, when one

replaces pegmatite or feldspar of a porcelain body by

spodumene, the coefficient of dilatation may be

lowered by 2 to 3 times compared to its value in a

feldspathic product."

-

- " In porcelain bodies in

which Li2O was added up to a total value of 2%, the

mechanical properties and the electrical resistance of

the shapes containing spodumene approach those of the

porcelains for high voltage (high voltage insulators).

The thermal dilatation coefficient is lower (1.5 to

2.5 x10-6 °C-1) in the range of 0 to

200°C."

-

- " A special attention is

to be paid to the conditions of cooling of the

products after firing. The pieces containing

approximately 2% Li2O which cool too slowly have

altered structures and are not very dense, their

dilatation is negative. V.G. AVETIKOV concludes that

this is due to recrystallizations of lithium

aluminosilicates caused by a too slow cooling."

-

- " To obtain dense

porcelain structures, the speed of cooling between

1300°C and 1100°C must be approximately

300°C per hour. Under these conditions the

thermal dilatation coefficient remains positive. The

speed of cooling under 1100°C does not affect the

quality of the shard."

-

- " The tendency to

recrystallize is directly related to the content in

Li2O."

-

- " The resistance to

thermal shock of the dense shards (not very porous)

increases with the amount of Li2O."

-

-

-

- Lithium favors

nucleation and growth in crystalline glazes :

-

-

- Lithium is generally

introduced in small quantities from 1 to 2% of Li2O in

this type of glaze.

-

- Upon cooling, lithium favors

the formation of crystalline aluminosilicates and in

particular the formation of spodumene from the

ingredients of the vitreous flow. These nucleations

allow to sow the glaze more quickly and improve its

crystallizing capacity.

- These glazes require a very

good control of the cycle of firing cooking in order

to pass to the phase of growth with precision. The

reproducibility of this type of glaze can be rather

difficult.

-

- The crystalline growth is

influenced by the active role of lithium which lowers

the viscosity and the surface tension of crystalline

glazes (*).

-

- A more fluid glaze favors a

faster growth of the crystals. It allows a more

important mobility of the crystallizing elements and

colourants and favors their migration.

-

- The reduction of surface

tension of the glaze favors crystals with low density

structures because these develop themselves and move

more freely on the surface of the glaze. They are to

some extent " more relaxed"…

-

- In short, with lithium low

viscosity more quickly nourishes the crystals and a

lower surface tension favors their not very dense

spreading out on the surface of the glaze. With a time

of growth adapted, a crystalline glaze with lithium (a

few % of Li2O) will rather easily give very large

crystals with diaphanous textures. ("transparency" and

"wings of dragonfly" effects ).

-

-

- It is the same for the other

types of glazes whose viscosity and surface tension

are close to those with lithium.

-

- But attention to glaze

runs…

-

-

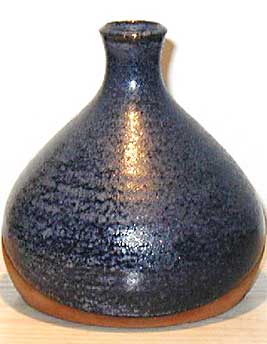

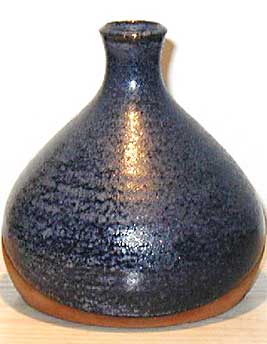

- example of

semi-translucent zinc silicate crystals on a glaze

with lithium (2.5% Li2CO3)

-

-

- (*) : Caution!! Here it

is question of crystalline glazes, therefore of glazes

with heterogeneous phases (vitreous and crystalline).

Calculations of physical properties applied to pure

glasses, such as those of the thermal dilatation

coefficient, superficial tension, elasticity, cannot

be applied to these compositions.

-

-

- Toxicity of lithium :

-

-

- See Edouard Bastarache's

article on lithium (Québec) : Lithium.htm

-

-

- Examples of lithium

containing glazes :

-

-

-

-

CONE 04

Lithium Containing Glazes -

(1060-1080°C) - From : Edouard

Bastarache (https://www.blogger.com/profile/10622613356744391469)

-

- 01

- Sorel Jade Green Glaze

Recipe

by Edouard

Bastarache https://04glazes.blogspot.com/

|

|

- Firing:

Orton cone 04

- North

American raw materials were

substituted for by European

ones.

|

|

Washed

hardwood ash (Oak)

|

36

|

|

Mixed

Feldspar ICE10

|

14.5

|

|

Ferro

Frit 3134 (available in

Europe)

|

23

|

|

Kaolin

|

14.5

|

|

Lithium

carbonate

|

12

|

|

Bentonite

|

2

|

|

Zircon

(Zirconium silicate)

|

15.5

|

|

Black

copper oxide

|

3.5

|

|

Shiny

glaze with areas of surface

microcrystals (spodumene

crystallizations at the time of

cooling).

|

-

- 02

- Ginette's Blue Glaze (My

wife)

Recipe

by Edouard

Bastarache https://04glazes.blogspot.com/

|

|

- Firing

: Orton cone 04

- North

american raw materials were

substitued for european

ones.

|

|

Washed

hardwood ash (oak)

|

35

|

|

Mixed

feldspar ICE10

|

14

|

|

Ferro

frit 3134 (available in

Europe)

|

25

|

|

Kaolin

|

14

|

|

Lithium

carbonate

|

12

|

|

Bentonite

|

2

|

|

Zircon

(Zirconium silicate)

|

15

|

|

Black

cobalt oxide

|

5

|

- Shiny

glaze with areas of surface

microcrystals (spodumene

crystallizations at the time

of cooling).

-

- Richard

Zakin says that we should not

put more than 5% Lithium

Carbonate in a glaze (in his

software Describ9) because

once applied, the dry glaze

can crack and flake

off.

-

- We

checked that and it is true,

then the trick is to rub the

glaze while the shard is still

wet considering the recent

application of the glaze; and

it works.

- As

for Spodumene, it is the same

thing (to flake off). He also

says not to put more than 35%

Spodumene.

|

-

-

- LITHIUM

CRYSTALLINE Glaze for Cone 6

(1220-1240°C) - From John Sankey's

database

(https://www.johnsankey.ca/glazedata.html)

-

- 03 -

Turquoise Crystalline Glaze

Recipe

by Alisa

Clausen https://www.flickr.com/photos/glazes/

|

|

- Firing

: cône cone 6

- Cooling

: fast down to 1100°C then

lowering to 800°C at

80°C per hour

|

|

Potassium

feldspar

|

36

|

|

Zinc

oxide

|

24

|

|

Silica

|

15

|

|

Calcium

carbonate

|

13

|

|

Lithium

carbonate

|

7

|

|

Kaolin

|

5

|

|

Rutile

|

5

|

|

Copper

carbonate

|

1

|

|

Shiny

very fluid glaze with large green

and blue crystals.Looks like an

aerial view of the Caribbean

islands. The crystals have clear

structures like gems.

|

- 04 -

Orange - Blue Crystalline

Glaze

Recipe

by Alisa

Clause https://www.flickr.com/photos/glazes/

|

|

- Firing

: Orton cone 6

- Cooling

: fast down to 1100°C then

down to 800°C at 80°C

per hour.

|

|

Potassium

feldspar

|

36

|

|

Zinc

oxide

|

24

|

|

Silica

|

15

|

|

Calcium

carbonate

|

13

|

|

Lithium

carbonate

|

7

|

|

Kaolin

|

5

|

|

Black

nickel oxide

|

1

|

|

Orange

to rusty glqze background with large

luminous blue crystals and dark blue

centers. The crystals have clear

structures like gems.

|

- GLAZES

containing lithium for cone 9.5

(1280-1300°C) - From : Edouard

Bastarache (https://www.blogger.com/profile/10622613356744391469)

-

- 05 -

White-Rusty Shino

glaze

Recipe

by Edouard

Bastarache

|

|

- Firing

: Orton cone 9.5 in

reduction

|

|

Nepheline

syenite

|

86

|

|

Kaolin

|

3

|

|

Silica

|

4

|

|

Alumina

hydrate

|

3

|

|

Lithium

carbonate

|

4

|

|

Bentonite

|

3

|

|

White

and rusty glaze due to the clay

containing iron.

Lithium

carbonate is added to thwart the

surface flaws generated by the

excess of Nephelite/Syenite (Na2O).

|

- 06 -

Brick Red Shino

Recipe

by Edouard

Bastarache

|

|

|

Firing :

Orton cone 9.5 in

reduction

The North

American raw materials were

substituted for by European

ones.

|

|

Nepheline

syenite

|

42

|

|

Mixed

Feldspar ICE10

|

44

|

|

Kaolin

|

11

|

|

Lithium

carbonate

|

3

|

|

Bentonite

|

4

|

|

Red iron

Oxide

|

2

|

- Textured

brick red glaze

|

|

-

-

-

-

-

-

-

- Smart2000.fr

©

Septembre 2011

-

FRANCE

- Écrit

et documenté par le propriétaire du site

// Contact : Smart2000@wanadoo.fr

- Document

pour CONSULTATION PRIVÉE uniquement - Toute

reproduction totale ou partielle est

interdite

-

-

-

-

- Smart2000.fr

le site

dédié aux passionnés de

céramique

-

- Smart2000

- FRANCE sur https://smart2000.fr/

-

- This

entire page Copyright © 2011-2023, All Rights

Reserved.

- Les

textes et les photos restent la

propriété de leur auteurs, ils ne

peuvent être réutilisés sans un

accord préalable. Nous

consulter.

|